In the fast-paced world of eCommerce, automation is king. With just a few clicks, products from halfway across the world can find themselves instantly listed on your Shopify store, thanks to dropshipping apps that promise rapid product imports and seamless inventory syncing. But what happens when that automation breaks down? This is a true cautionary tale of how one online store was thrown into disarray — and the powerful manual inventory process they implemented that eventually saved them from total disaster.

TL;DR

Dropshipping apps that offer “one-click import” and automated inventory syncing can seem efficient but often fail to ensure SKU accuracy, leading to overselling and order cancellations. One store faced order chaos during a major sales event when the app failed to detect out-of-stock items from suppliers. Afterward, they created a manual inventory verification flow to cross-check supplier stock before listing new products. It wasn’t as fast, but it gave them back control — and their customers’ trust.

The Allure of One-Click Dropshipping

You’ve likely seen the advertisements: “Add products to your store in seconds!” “Import thousands of items with one click!” Apps like Oberlo, Spocket, and AutoDS promise an eCommerce utopia where store owners can focus on marketing and scaling while the backend practically runs itself.

This level of automation hooks new entrepreneurs with:

- Product discovery & import: Finding trending products and instantly importing them with recommended descriptions and images.

- Price automation: Automatically setting sell prices based on cost margins.

- Inventory syncing: Supposed real-time updates from suppliers informing your store whether items are in stock or out of stock.

Sounds ideal, right? Except when it isn’t.

Where It All Went Wrong

Meet Kara, a solo eCommerce founder running a Shopify clothing boutique powered entirely by dropshipping. Her store, EverAsh & Co, quickly gained traction thanks to influencer partnerships and clever marketing on TikTok. Kara built her store with an app that allowed her to import products with “one-click.” Each imported product included descriptions, pricing, and an assurance that inventory syncing would be handled automatically.

During a seasonal flash sale, Kara saw over 300 orders flood in for a bestselling lace duster cardigan — a product sourced from a popular Chinese supplier via the app. It wasn’t until 48 hours later, amidst mounting customer inquiries, that she realized the supplier had run out of stock days before the sale even started.

The app never updated the inventory count. The real kicker? The supplier didn’t plan to restock for another month. Over 200 customers had ordered a product that no longer existed in her supply chain.

The Fallout: Lost Dollars and Loyalty

The cost of this inventory mismatch was staggering:

- Over $6,000 in canceled orders due to stockouts.

- Dozens of refund processing fees from the payment gateway providers.

- Heat from angry customers who left negative reviews on Trustpilot and social media.

- One influencer partnership terminated because of the bad PR fallout.

Trust — Kara’s most precious commodity — was shattered. The allure of full automation had failed spectacularly. Automated systems are only as good as the data they receive, and in this case, the supplier’s system either didn’t update inventory quickly enough, or the app failed to sync the changes in time. Either way, Kara was left scrambling to control the mess.

Why “One-Click” Isn’t One-Size-Fits-All

What Kara — and many other new sellers — didn’t realize is that these automated apps often rely on API connections or scraping tools to pull inventory data. But:

- Not all suppliers update frequently.

- Time zone differences can create stock lag.

- Multichannel sellers may sell out on Amazon or eBay without the app catching up fast enough for your store.

This kind of breakdown is common, especially during peak seasons. When the dependency chain includes:

- Your store

- The dropshipping app

- A middleman fulfillment center

- The supplier

…there are simply too many points of potential failure for 100% blind trust.

The Inventory Check Flow That Rebuilt the Business

After the disaster, Kara didn’t just patch things up — she reengineered her workflow.

Here’s the manual inventory verification flow she implemented that turned things around:

1. Supplier “Heartbeat Check”

Before importing any new product into the store, Kara now checks the supplier’s platform manually to verify stock quantity and restock frequency. She also sends a templated email to the supplier asking for:

- Estimated restock times

- Real-time inventory feed links (if available)

- Any known seasonality risks

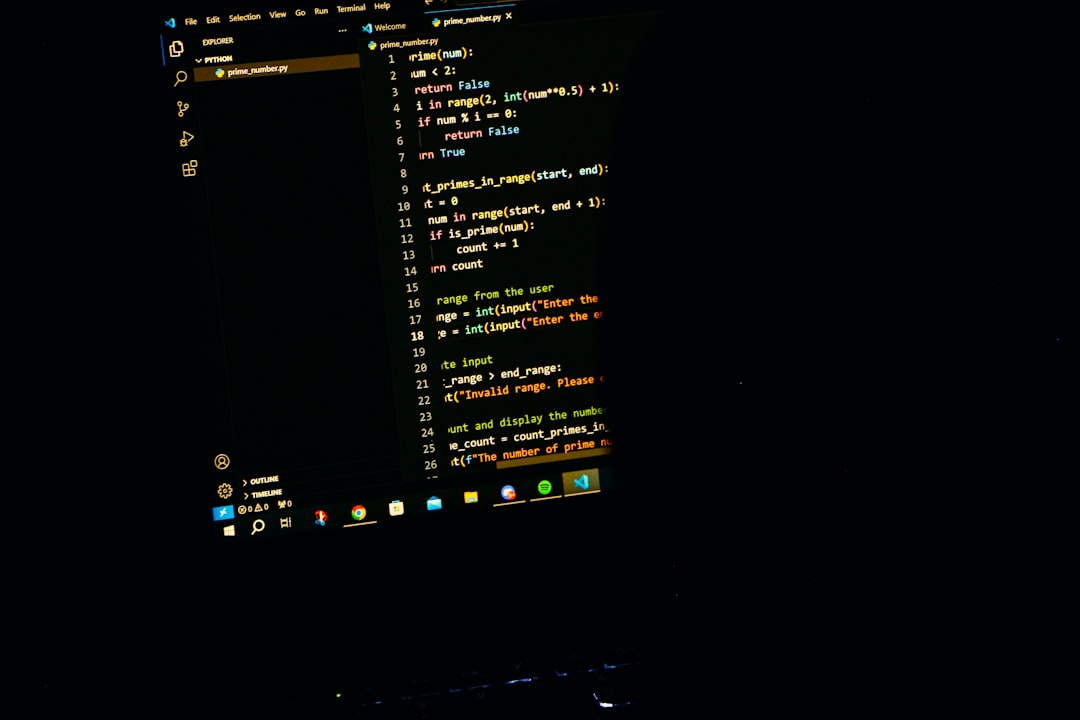

2. Google Sheet Sync Tracker

She created a connected Google Sheet that logs each product, its stock level at import time, and the time and date of last manual refresh. It includes color-coded risk indicators:

- Green = Updated within 24 hours

- Yellow = Over 48 hours old

- Red = Needs immediate re-verification

This sheet also became an internal dashboard for any future VA she hires.

3. “Double Opt-In” Listing Process

No product now goes live on the store until two confirmations are logged:

- The product’s quantity is confirmed within the last 6 hours

- A second person or Kara herself signs off on the sheet-to-store listing

While this added about 3–6 hours to her product sourcing pipeline, it reduced oversales down to zero after eight weeks of use.

The New Balance Between Automation and Control

Kara didn’t ditch her dropshipping app entirely — she still uses it for price markup rules and auto-fulfillment triggers. But inventory management? That’s back under human supervision. Her experience illustrates an important fact that often gets lost in the rush for efficiency:

Robust eCommerce doesn’t come from full automation — it comes from knowing when to intervene.

Key Takeaways for Any eCommerce Seller

- Validate dropshipping policies and what inventory syncing actually means for each app you use.

- Contact your suppliers directly and ask for a reliable version of their inventory data.

- Use a manual gating process to approve only reliable, regularly-stocked items to go live.

- Treat automation as an assistant, not an autopilot.

Conclusion: The Cost of Convenience

Automation is intoxicating — especially for solopreneurs trying to scale efficiently. But for every time-saving feature, there’s potential for unseen risk. In Kara’s case, the “one-click” promise created a PR nightmare she had to untangle manually anyway. What she learned is invaluable, though: Guard your inventory flow as if every SKU is a limited-edition product drop. Because in the world of dropshipping, sometimes it is.

Next time you’re dazzled by an app demo showing instant imports and set-it-and-forget-it syncing — pause. Ask how often their inventory data is refreshed. Ask what happens if it isn’t. And most of all, ask yourself whether that promise of speed is worth the risk to your reputation.